90% of Scottish salt was made along the edges of the Firth of Forth and in the late 18th century Fife's best salt was said to come from three works: "Drummachie, Largo and St Monance", largely because of the salinity of the water they were able to draw on ('The Salt Industry and its Trade in Fife and Tayside' by C.A. Whatley).

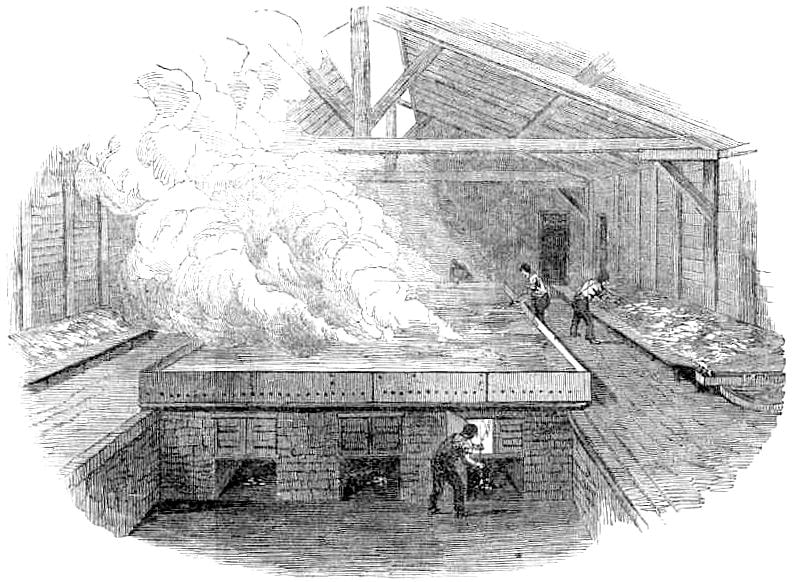

The 1/3 scale custom-made salt pan shown in the photograph was made for the 1722 Waggonway Project and it is based in the garden of Cockenzie House in East Lothian. A traditional salt pan was typically 18ft x 9ft and 18 inches deep.

1. sea water is collected from a tidal reservoir in the rocks near the shoreline (often referred to as a 'bucket pot' because originally buckets were used to collect the water - although pumps and windmills were often used later).

2. the water is poured into the pan which is hot from the fire beneath it and evaporation begins.

3. prior to boiling, egg white is added to the warming water in order to gather up any impurities (in the past blood was sometimes used rather than egg white).

4. the resulting scum can then be skimmed off the surface.

The images below illustrate:

5. calcium carbonate separating from the water

6. a salt crust appearing on the surface while the remaining water simmers below

7. the residual water evaporating through cracks and holes in the salt crust (furnace heat is low at this point)

8. the hot salt being drawn to the sides of the pan to drain briefly before being transferred into baskets and stored in the girnel (storehouse).

RSS Feed

RSS Feed